AAA weekly

2019-11-25

Copyright FOURIN, Inc. 2025

Solving of Inverse Problems Enables Non-destructive Battery Inspection

Based on an interview with Kenjiro Kimura (Professor, Kobe University) at Kobe University Incubation Center (Kobe, Hyogo Prefecture, Japan) on September 24, 2019)

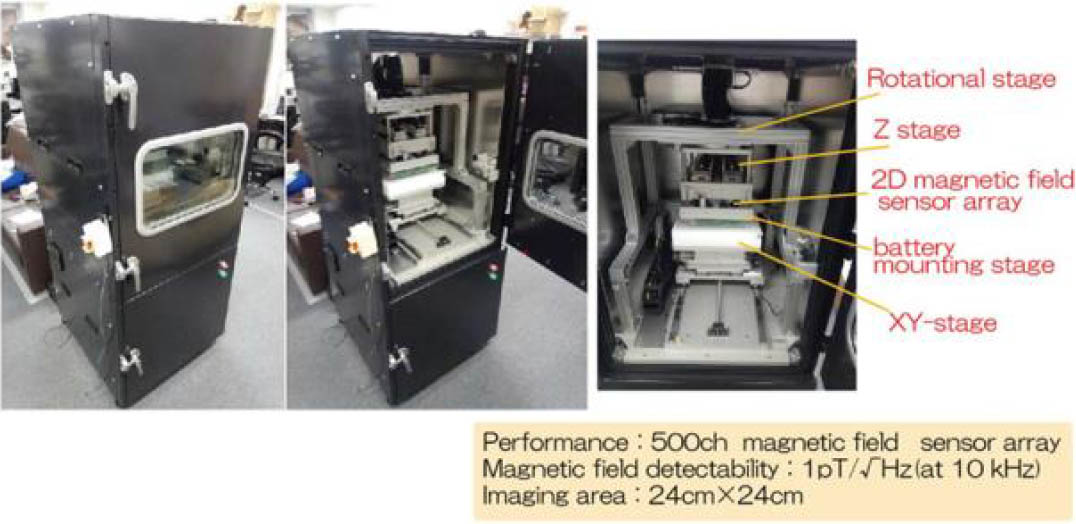

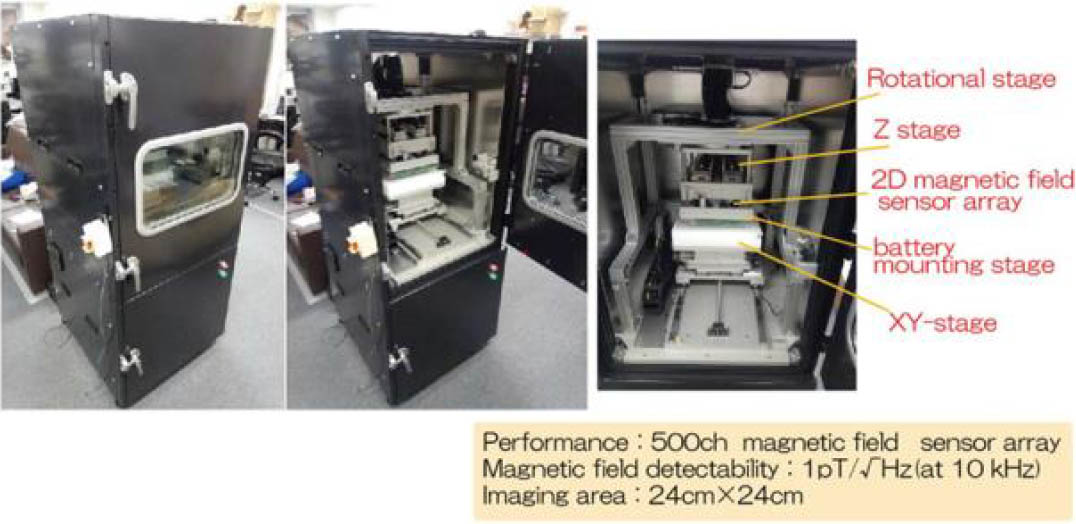

Kobe University’s venture Integral Geometry Science has the world’s top technology in image reconstruction and high-precision measurement for analytically solving inverse problems. The company has put into practical use a system for non-destructive inspection of the current distribution in the battery and is currently preparing for the launch of an in-line inspection system. FOURIN has interviewed Mr. Kenjiro Kimura who is a Professor at Kobe University as well as the founder of Integral Geometry Science.

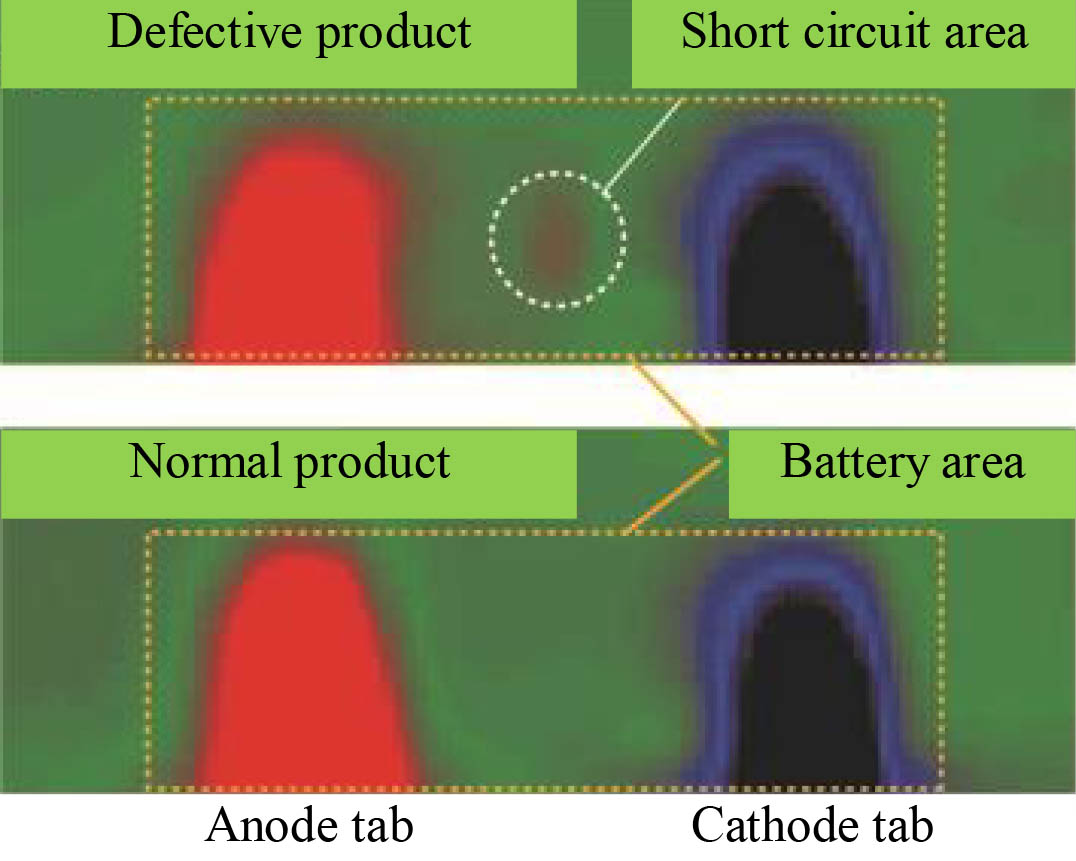

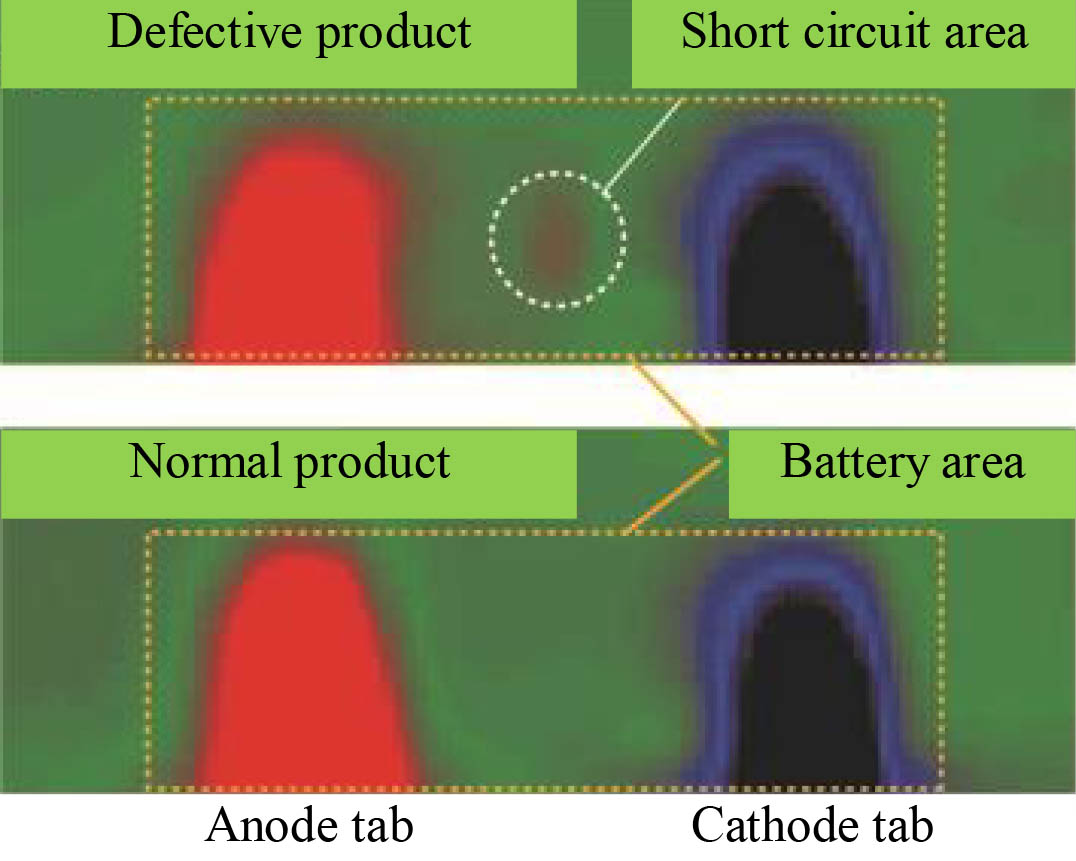

The basis of the system developed by Professor Kimura and Integral Geometry Science is an analytical solution for the inverse problem that derives the cause from the observation results. Observing the magnetic field at a distance from the source of the magnetic field usually produces only a blurred image, but by mathematically analyzing this, the current state of the source can be clearly revealed. The batteries that have been shipped as normal products until now included batteries with non-uniform current distribution. These defective batteries can be identified by Professor Kimura’s system. In addition, since an analytical solution is used, that is, a mathematical expression for deriving a current distribution, determination can be made instantaneously even with a commercially available personal computer.

Professor Kimura and his colleagues are also working on the development of an automatic driving system that embeds a magnetic marker (magnetic bar code) in the road surface and determines the course while reading it with an in-vehicle sensor. Major companies have repeated demonstration tests so far, but malfunctions have become a problem caused by manholes, nails, puddles and other obstructions. Professor Kimura’s team has also applied a calculation algorithm that analytically solves the inverse problem and developed a system that reads magnetic markers accurately even at a vehicle speed of 200km/h. In FY2020, the company plans to start a demonstration experiment jointly with a major automobile manufacturer.

In addition to these, Professor Kimura and his team have made a wide range of technical proposals such as next-generation sensing that exceeds LiDAR.

Difficulty of Measuring Internal Current from Magnetic Field

The in-battery non-destructive image diagnosis system applies a current to the battery and measures the magnetic field generated around the battery. By accurately measuring a weak magnetic field and solving the inverse problem, the state of the internal current can be derived from the magnetic field.

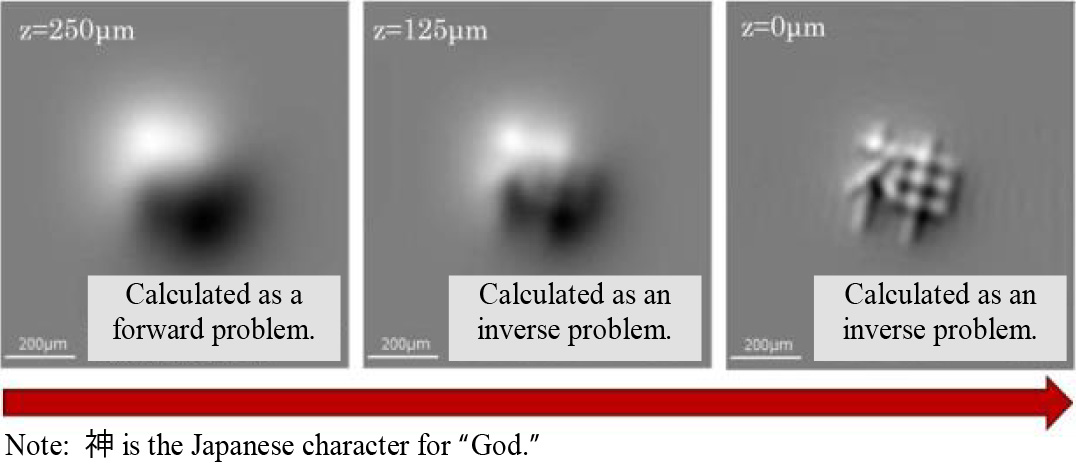

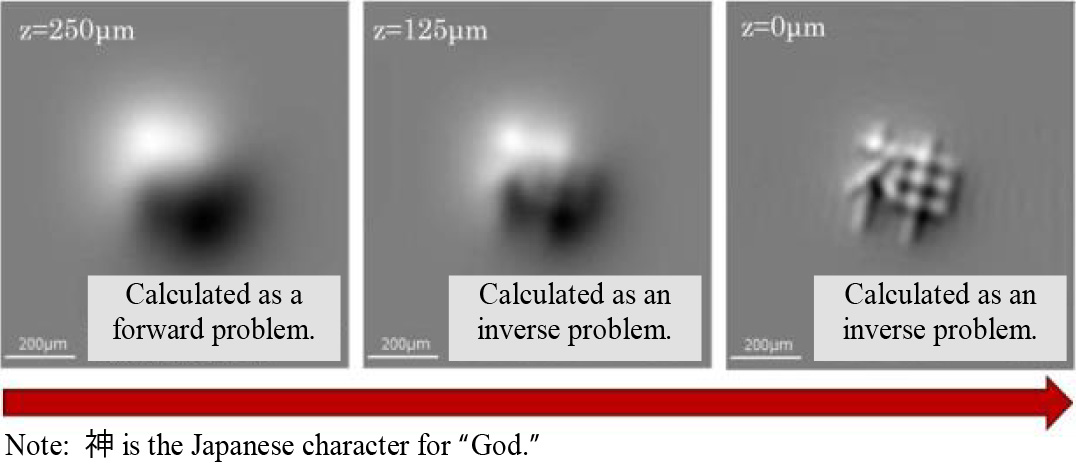

In that case, the key is to solve the inverse problem of deriving the three-dimensional current density distribution in the battery from the reconstruction theory of the electromagnetic field and the surrounding magnetic field. The magnetic field becomes blurred as the distance increases. In the blurred state, it is not possible to know what is happening, so it is necessary to restore the blurred object to a clear shape. At the heart of this reconstruction theory is the inverse problem of deriving current from a magnetic field.

It is obvious if you see the conceptual diagram above. Let’s say the current is flowing in the form of the Japanese character for “God.” It is blurred when the magnetic field is measured at a distance. Returning from this blurred state (left) to a clear state (right) solves the inverse problem.

The forward problem of deriving the surrounding magnetic field from the source current is easy as long as there is an equation. However, the inverse problem of deriving the source current from the magnetic field distribution is difficult. Although it is generally impossible to solve this analytically, we have succeeded in finding an analytical solution for the inverse problem of the internal current in a storage battery and the magnetic field leaking to the periphery. Previously, the only way to solve this problem was to solve the forward problem repeatedly and use a technique that combines the measurement data with the calculation results. From the analysis result, it is a groundbreaking thing to visualize local current concentration and current unevenness.

The diagnosis of the battery by this device is basically performed instantaneously. A defective product can be determined in a few seconds.

Advantages of Non-destructive Imaging Diagnosis

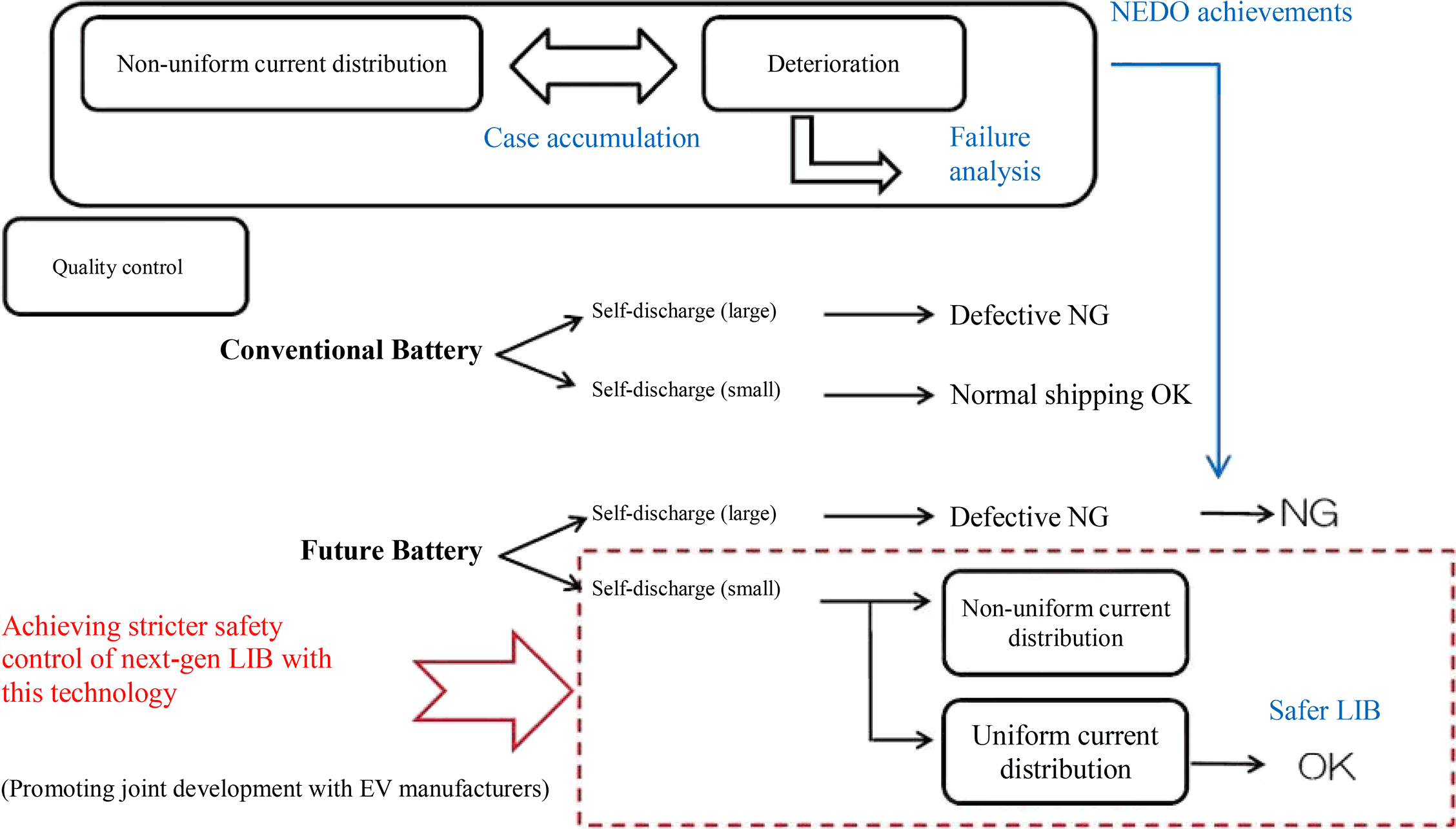

There is a great merit in a system for non-destructive imaging diagnosis of the current inside the battery.

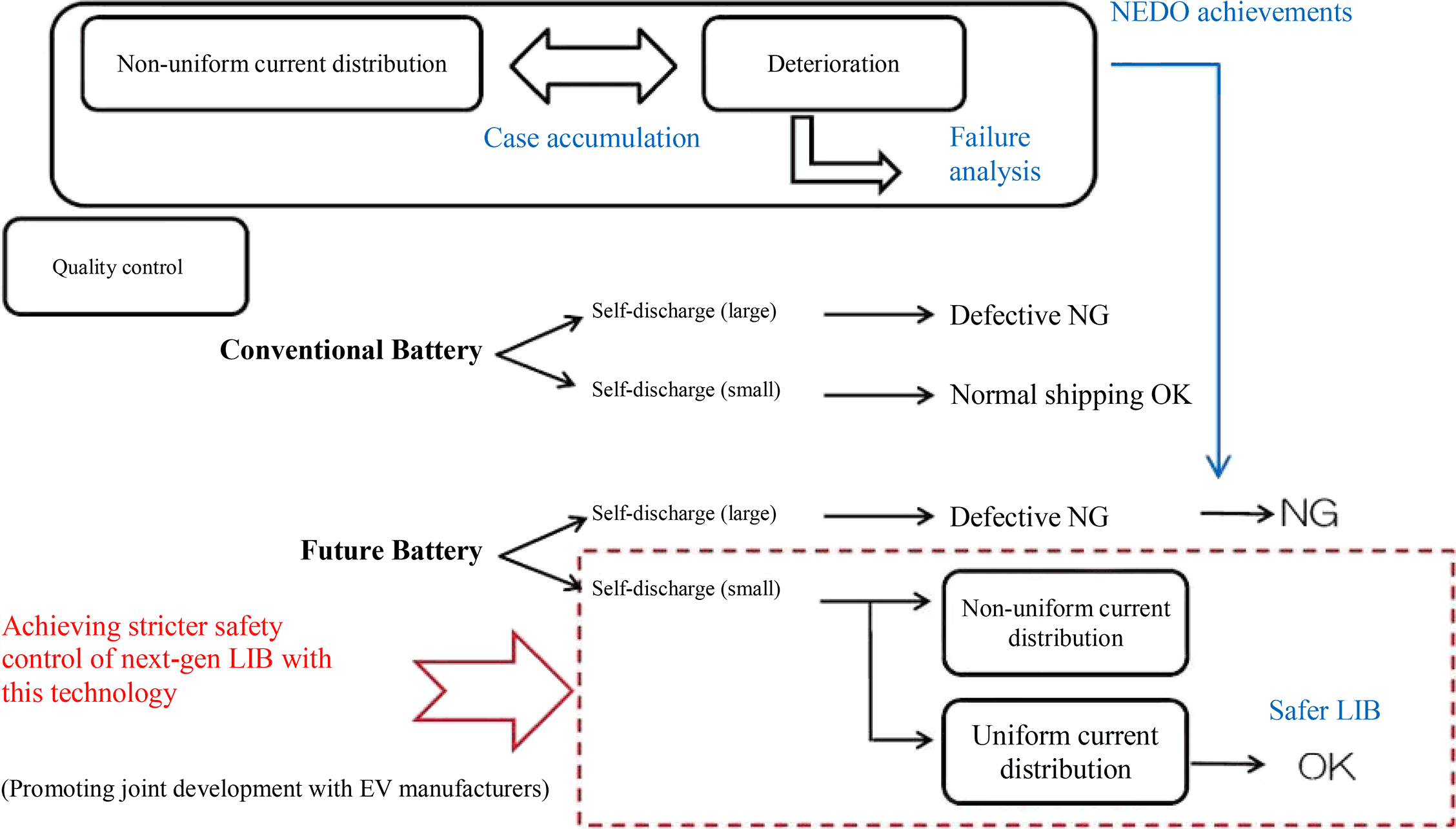

In the field of battery quality control, the magnitude of self-discharge has been measured so far. Diagnosis has been made such that a large self-discharge makes a battery defective and a small one makes it non-defective.

However, using an in-battery non-destructive image diagnosis system, it is possible to sort out current distribution that is not uniform and current distribution that is uniform given that the batteries have a small self-discharge.

Finding Defective Batteries at Risk of Combustion Before Shipment

The graph below shows how many defective products that have been missed and shipped by the in-line battery imaging system are reduced.

Currently, the shipment rate of in-vehicle storage batteries is about 70%. A value of about several tens of μA is set between the leakage current value of non-defective products and the defective products. The device finds batteries with relatively high leakage current among non-defective products, and classifies them into five types, ranging from uniformly uneven power generation to topical ones. If batteries showing the most uneven leakage current are disposed, problems in the market can be avoided.

If the power generation unevenness of each category occurs at the same rate, the conventional yield drops from 70% to 67%. In other words, 3% of defective products can be newly discovered, so it is possible to avoid putting batteries with a high combustion risk on the market.

About Kenjiro Kimura and Integral Geometry Science

Please

register or subscribe to view this report for free.

If you’re already a subscriber, sign in.

Credit card information is not needed for free trial registration.

You are eligible to view one report for free.

Additional reports require subscription.

The in-battery non-destructive image diagnosis system applies a current to the battery and measures the magnetic field generated around the battery. By accurately measuring a weak magnetic field and solving the inverse problem, the state of the internal current can be derived from the magnetic field.

In that case, the key is to solve the inverse problem of deriving the three-dimensional current density distribution in the battery from the reconstruction theory of the electromagnetic field and the surrounding magnetic field. The magnetic field becomes blurred as the distance increases. In the blurred state, it is not possible to know what is happening, so it is necessary to restore the blurred object to a clear shape. At the heart of this reconstruction theory is the inverse problem of deriving current from a magnetic field.

It is obvious if you see the conceptual diagram above. Let’s say the current is flowing in the form of the Japanese character for “God.” It is blurred when the magnetic field is measured at a distance. Returning from this blurred state (left) to a clear state (right) solves the inverse problem.

The forward problem of deriving the surrounding magnetic field from the source current is easy as long as there is an equation. However, the inverse problem of deriving the source current from the magnetic field distribution is difficult. Although it is generally impossible to solve this analytically, we have succeeded in finding an analytical solution for the inverse problem of the internal current in a storage battery and the magnetic field leaking to the periphery. Previously, the only way to solve this problem was to solve the forward problem repeatedly and use a technique that combines the measurement data with the calculation results. From the analysis result, it is a groundbreaking thing to visualize local current concentration and current unevenness.

The diagnosis of the battery by this device is basically performed instantaneously. A defective product can be determined in a few seconds.

The in-battery non-destructive image diagnosis system applies a current to the battery and measures the magnetic field generated around the battery. By accurately measuring a weak magnetic field and solving the inverse problem, the state of the internal current can be derived from the magnetic field.

In that case, the key is to solve the inverse problem of deriving the three-dimensional current density distribution in the battery from the reconstruction theory of the electromagnetic field and the surrounding magnetic field. The magnetic field becomes blurred as the distance increases. In the blurred state, it is not possible to know what is happening, so it is necessary to restore the blurred object to a clear shape. At the heart of this reconstruction theory is the inverse problem of deriving current from a magnetic field.

It is obvious if you see the conceptual diagram above. Let’s say the current is flowing in the form of the Japanese character for “God.” It is blurred when the magnetic field is measured at a distance. Returning from this blurred state (left) to a clear state (right) solves the inverse problem.

The forward problem of deriving the surrounding magnetic field from the source current is easy as long as there is an equation. However, the inverse problem of deriving the source current from the magnetic field distribution is difficult. Although it is generally impossible to solve this analytically, we have succeeded in finding an analytical solution for the inverse problem of the internal current in a storage battery and the magnetic field leaking to the periphery. Previously, the only way to solve this problem was to solve the forward problem repeatedly and use a technique that combines the measurement data with the calculation results. From the analysis result, it is a groundbreaking thing to visualize local current concentration and current unevenness.

The diagnosis of the battery by this device is basically performed instantaneously. A defective product can be determined in a few seconds.