AAA weekly

2019-11-11

Copyright FOURIN, Inc. 2025

Electric Water Pumps Independent from Engine Rotation Are Increasingly Adopted in the EV Sector

Electric water pumps (EWP) that can finely adjust the cooling water are gaining popularity as the number of idle-stop and hybrid vehicles increases.

Energy efficiency of hybrid vehicles (HEV, PHEV, 48V MHEV) is better when the auxiliary devices are high voltage. Auxiliary equipment that can support everything from the conventional 12V system to the 48V (MHEV) and 200V (HEV) systems has increased. EWP is one of them.

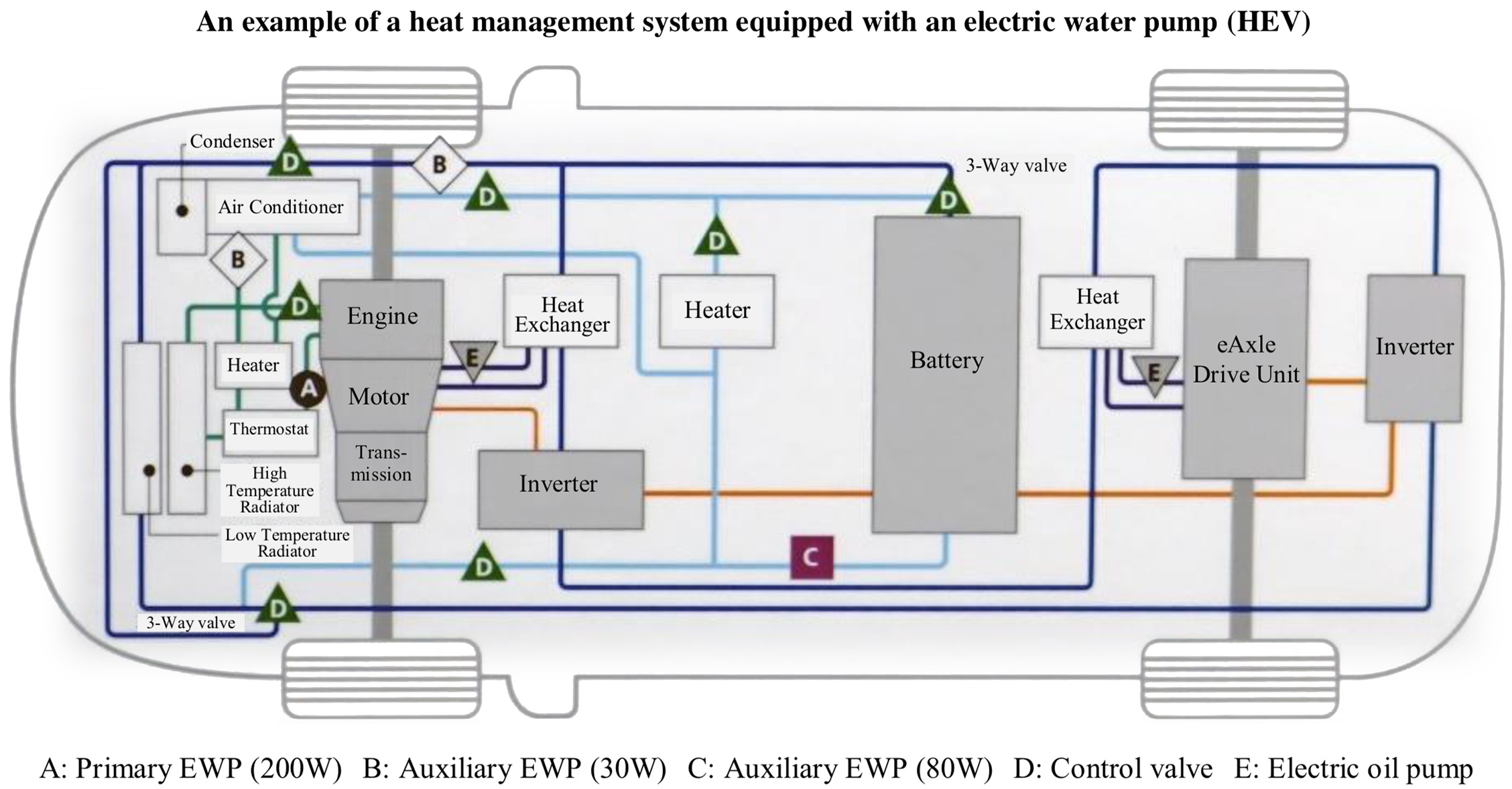

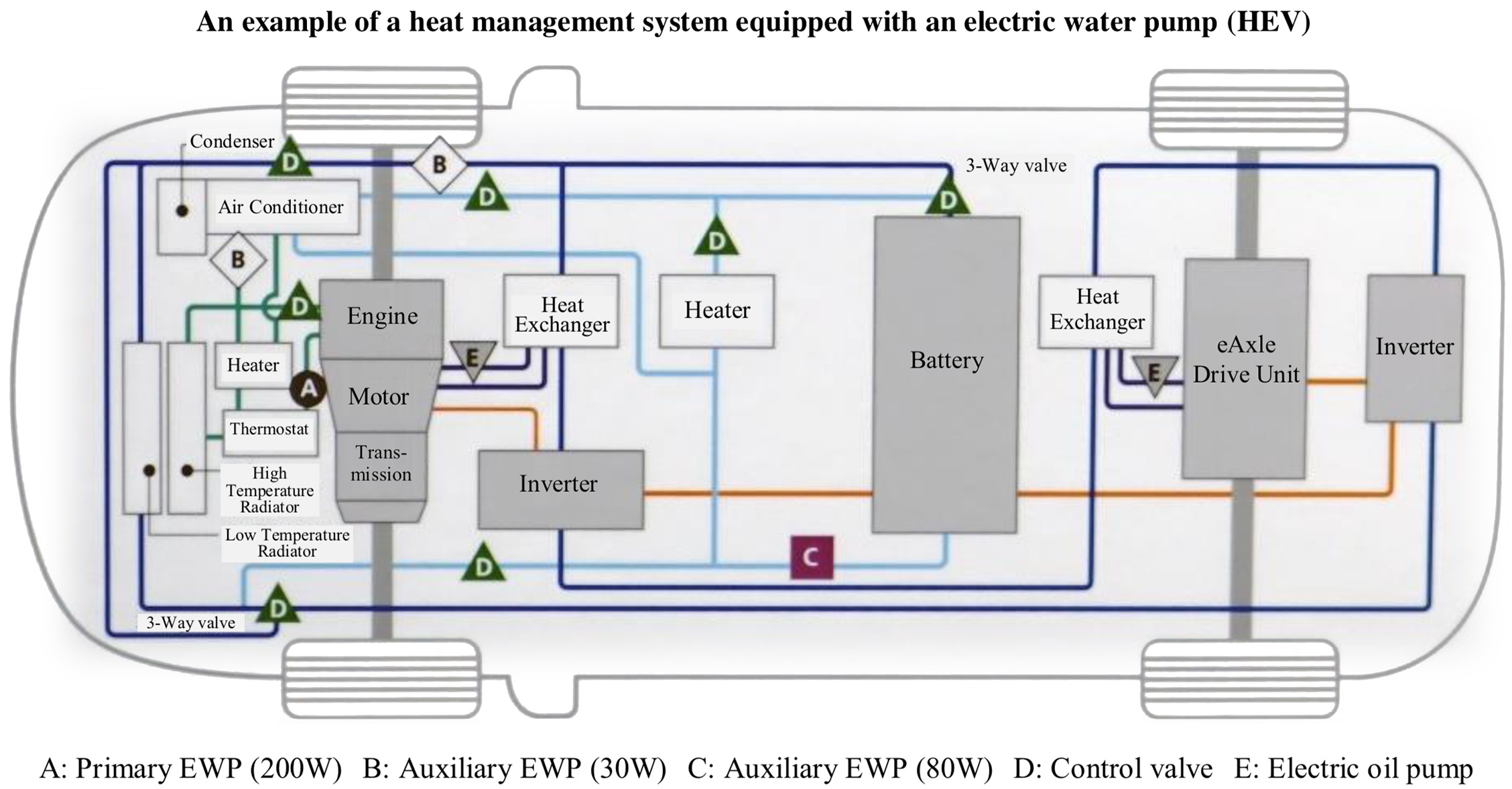

Water pumps are part of the car’s heat management system. Cooling water cooled by a radiator is sent by the water pump to the engine under pressure, cooling down the engine to maintain an optimum temperature. When the first (primary) water pump arranged close to the engine is mechanical, the operation is interlocked with the rotation of the engine. On the other hand, EWP allows continuous variable control without depending on engine rotation. They are effective for reducing exhaust gas and facilitating warm air at cold start. EWP is also compatible with the high voltage 48V and strong hybrids.

EWPs are used to cool engines, inverters and other auxiliary equipment in 12V start / stop vehicles and hybrid vehicles. They are also used to maintain the optimum temperature of electronic units such as batteries, inverters, and motors in battery electric vehicles.

Looking at supplier activities, Nidec GPM is aiming for growth in the EWP market by combining the pump technology of Germany’s GPM, a major European water pump maker acquired by Nidec in 2014, with its own motor technology and the ECU technology of Nidec Elesis. A next generation EWP module, which combines a small motor (actuator) with a water pump and ECU, will be put forth by the company as a pillar of its future water pump business.

Magna quickly responded to the current electrification trend and developed 48V series and 12V high-power EWP. Thanks to actual orders from OEMs, the Magna launched mass-production ahead of other companies. The company offers EWPs as one of the integrated electrification components. Magna says its EWP can reduce CO2 by up to 2 percent (WLTC).

Meanwhile, proposals in accordance with new requirements are also coming forth in the mechanical water pump sector. Pierburg Mikuni Pump Technology (PMP), a joint venture between Japan’s Mikuni and Germany’s Rheinmetall has developed a new variable water pump using a sliding ring. The cooling water supply flow rate can be adjusted by the sliding ring covering the outer diameter of the impeller.

Water Pump Market Trends: Increase in Electric Water Pumps

・Electric water pumps (EWPs) that allow delicate and precise adjustment of cooling water regardless of whether the engine is rotating or not rotating are on the rise along with the increase in idle stop (12V start / stop system) and hybrid vehicles. The introduction of EWPs will surely increase further in the future.

– In case of hybrid vehicles such as HEVs (PHEVs) and 48V MHEVs, it is more energy efficient to make auxiliary equipment higher voltage.

– Auxiliary equipment that can support everything from the conventional 12V system to the 48V (MHEV) and 200V (HEV*) systems has increased.

– In addition, it is also necessary for the of support communication standards such as CAN and LIN in conjunction with in-vehicle communication systems and connected systems.

– EWPs make up about 20-30 percent of the total water pump market.

・Water pumps are part of the car’s heat management system. Cooling water cooled by a radiator is sent by the water pump to the engine under pressure, cooling down the engine to maintain an optimum temperature.

– Water pumps are roughly divided into mechanical types and actuator-driven electric types.

– The first (primary) water pump is placed close to the engine.

– Since the conventional mechanical water pump rotates via a timing belt or a fan belt, the operation is linked to the rotation of the engine.

– On the other hand, EWPs do not depend on engine rotation. They are effective for reducing exhaust gas and facilitating warm air at cold start. They also compatible with high voltages including 48V. Along with the increase of electric vehicle use, the use of EWPs is also expected to grow.

– An auxiliary (second / secondary) EWP is additionally used combined with a mechanical or electric primary water pump.

– EWPs are used to cool engines, inverters and other auxiliary equipment in 12V start / stop vehicles and hybrid vehicles. They are also used to maintain the optimum temperature of electronic units such as batteries, inverters, and motors in battery electric vehicles.

・In addition, control valves are another component of the vehicle’s water cooling system.

・Similarly to the electrification of the water cooling system, the oil cooling

system is fitted with an electric oil pump and the air cooling system with an electric radiator. Furthermore, the addition of a thermal management module which replaces the conventional thermostat advances the electrification of thermal management system.

*Starting with the 2009 Prius, Aisin Seiki has been supplying EWPs to Toyota THS (200V HEV system) installed into the Camry HV among other models.

(Created based on interview at Aisin Group’s booth at Automotive Engineering Exposition 2019 Yokohama, company PR materials and various media sources)

Please

register or subscribe to view this report for free.

If you’re already a subscriber, sign in.

Credit card information is not needed for free trial registration.

You are eligible to view one report for free.

Additional reports require subscription.

・Electric water pumps (EWPs) that allow delicate and precise adjustment of cooling water regardless of whether the engine is rotating or not rotating are on the rise along with the increase in idle stop (12V start / stop system) and hybrid vehicles. The introduction of EWPs will surely increase further in the future.

– In case of hybrid vehicles such as HEVs (PHEVs) and 48V MHEVs, it is more energy efficient to make auxiliary equipment higher voltage.

– Auxiliary equipment that can support everything from the conventional 12V system to the 48V (MHEV) and 200V (HEV*) systems has increased.

– In addition, it is also necessary for the of support communication standards such as CAN and LIN in conjunction with in-vehicle communication systems and connected systems.

– EWPs make up about 20-30 percent of the total water pump market.

・Water pumps are part of the car’s heat management system. Cooling water cooled by a radiator is sent by the water pump to the engine under pressure, cooling down the engine to maintain an optimum temperature.

– Water pumps are roughly divided into mechanical types and actuator-driven electric types.

– The first (primary) water pump is placed close to the engine.

– Since the conventional mechanical water pump rotates via a timing belt or a fan belt, the operation is linked to the rotation of the engine.

– On the other hand, EWPs do not depend on engine rotation. They are effective for reducing exhaust gas and facilitating warm air at cold start. They also compatible with high voltages including 48V. Along with the increase of electric vehicle use, the use of EWPs is also expected to grow.

– An auxiliary (second / secondary) EWP is additionally used combined with a mechanical or electric primary water pump.

– EWPs are used to cool engines, inverters and other auxiliary equipment in 12V start / stop vehicles and hybrid vehicles. They are also used to maintain the optimum temperature of electronic units such as batteries, inverters, and motors in battery electric vehicles.

・In addition, control valves are another component of the vehicle’s water cooling system.

・Similarly to the electrification of the water cooling system, the oil cooling

system is fitted with an electric oil pump and the air cooling system with an electric radiator. Furthermore, the addition of a thermal management module which replaces the conventional thermostat advances the electrification of thermal management system.

*Starting with the 2009 Prius, Aisin Seiki has been supplying EWPs to Toyota THS (200V HEV system) installed into the Camry HV among other models.

(Created based on interview at Aisin Group’s booth at Automotive Engineering Exposition 2019 Yokohama, company PR materials and various media sources)

・Electric water pumps (EWPs) that allow delicate and precise adjustment of cooling water regardless of whether the engine is rotating or not rotating are on the rise along with the increase in idle stop (12V start / stop system) and hybrid vehicles. The introduction of EWPs will surely increase further in the future.

– In case of hybrid vehicles such as HEVs (PHEVs) and 48V MHEVs, it is more energy efficient to make auxiliary equipment higher voltage.

– Auxiliary equipment that can support everything from the conventional 12V system to the 48V (MHEV) and 200V (HEV*) systems has increased.

– In addition, it is also necessary for the of support communication standards such as CAN and LIN in conjunction with in-vehicle communication systems and connected systems.

– EWPs make up about 20-30 percent of the total water pump market.

・Water pumps are part of the car’s heat management system. Cooling water cooled by a radiator is sent by the water pump to the engine under pressure, cooling down the engine to maintain an optimum temperature.

– Water pumps are roughly divided into mechanical types and actuator-driven electric types.

– The first (primary) water pump is placed close to the engine.

– Since the conventional mechanical water pump rotates via a timing belt or a fan belt, the operation is linked to the rotation of the engine.

– On the other hand, EWPs do not depend on engine rotation. They are effective for reducing exhaust gas and facilitating warm air at cold start. They also compatible with high voltages including 48V. Along with the increase of electric vehicle use, the use of EWPs is also expected to grow.

– An auxiliary (second / secondary) EWP is additionally used combined with a mechanical or electric primary water pump.

– EWPs are used to cool engines, inverters and other auxiliary equipment in 12V start / stop vehicles and hybrid vehicles. They are also used to maintain the optimum temperature of electronic units such as batteries, inverters, and motors in battery electric vehicles.

・In addition, control valves are another component of the vehicle’s water cooling system.

・Similarly to the electrification of the water cooling system, the oil cooling

system is fitted with an electric oil pump and the air cooling system with an electric radiator. Furthermore, the addition of a thermal management module which replaces the conventional thermostat advances the electrification of thermal management system.

*Starting with the 2009 Prius, Aisin Seiki has been supplying EWPs to Toyota THS (200V HEV system) installed into the Camry HV among other models.

(Created based on interview at Aisin Group’s booth at Automotive Engineering Exposition 2019 Yokohama, company PR materials and various media sources)