AAA weekly

2020-01-20

Copyright FOURIN, Inc. 2025

Water Injection Is Under Consideration to Meet Euro 7

The system that injects water into the air-fuel mixture of the engine became a hot topic in 2015 when the BMW M4 GTS sports car was launched fitted with Bosch’s water injector. There have been no subsequent manufacturers that released the same system. However, in recent years, research and development of water injection has been active again, especially in Europe. Water injection is considered to be a promising measure for the next European emission standard Euro 7 and for real driving emission (RDE) tests.

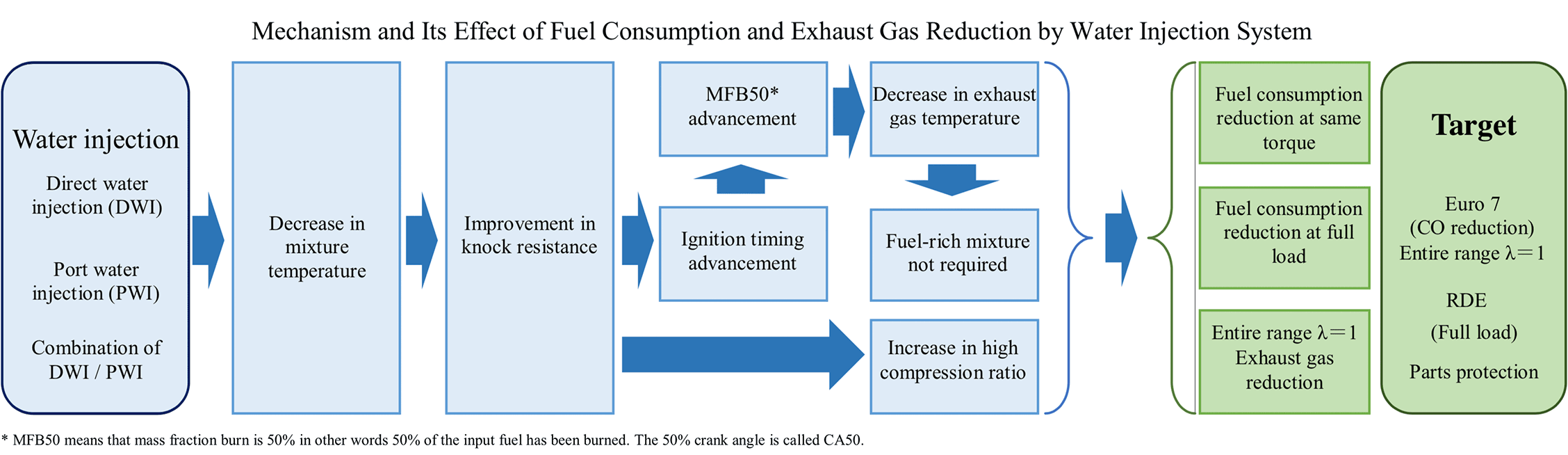

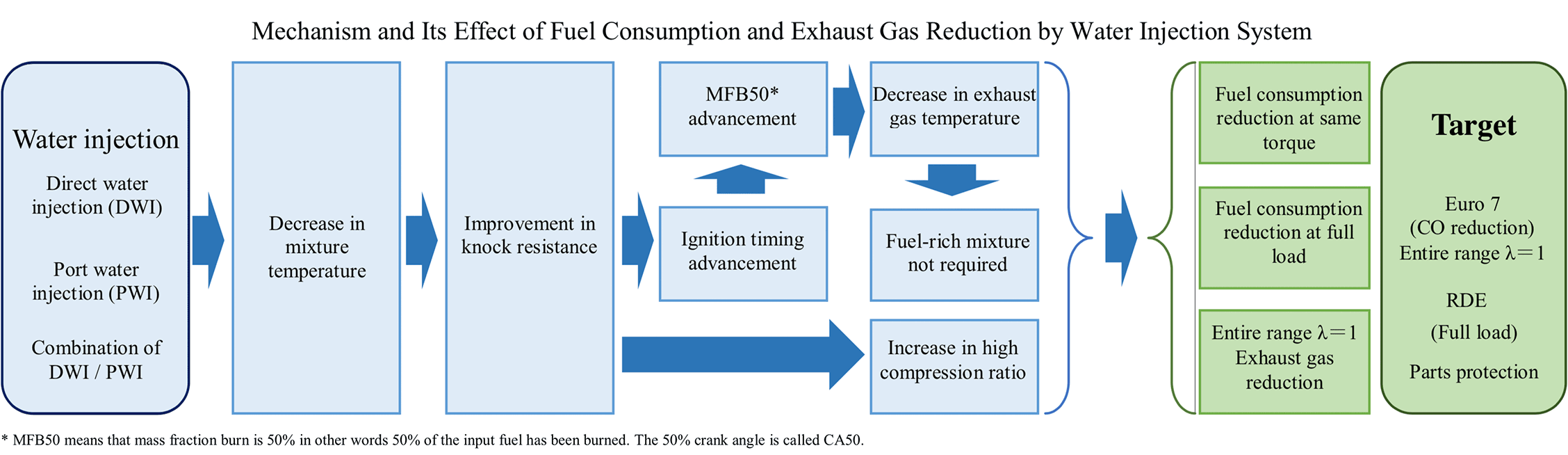

The water injection technology is based on the use of the latent heat of vaporized water which is about 5 to 6 times that of gasoline, having a high temperature reduction effect. By lowering the temperature of the air-fuel mixture, knock resistance can be improved and high compression ratio can be achieved. Since the water injector decreases the temperature of the exhaust gas, fuel-rich operation is not required. The system brings about low fuel consumption and low emissions.

RDE tests will continue even after the implementation of Euro 7. Moreover, carbon monoxide (CO) is expected to be newly regulated. In a gasoline engine, the three-way catalyst works effectively only when the engine is operating at stoichiometry (excess air ratio λ = 1). CO cannot be completely removed with a fuel-rich mixture of λ < 1. In other words, Euro 7 requires the whole range λ = 1. Furthermore, in consideration of full-load operation in RDE tests, it is difficult to adopt any conventional method of retarding ignition timing in order to limit knocking. In addition, in order to protect the turbocharger from having limited heat resistance, some measure for reducing the exhaust gas temperature is required. For this reason, water injection is now under consideration.

However, there are some issues with promoting water injection. The biggest challenge is water consumption. The BMW M4 GTS is fitted with a 5.0L water tank, but the water tank must be refilled once after every five fuel refills under normal driving conditions. Water consumption can further increase depending on weather conditions and driving style. In order to reduce the amount of water used, the size, pressure, temperature, spray position, spray control and other factors of the water droplets need to be continuously improved. In addition to installing a water tank, several manufacturers are also considering ways to collect condensed water from the vehicle’s air conditioner and radiator.

Water Injection System:

Effect Mechanism and Issues of Fuel Consumption and Exhaust Gas Reduction

Effectiveness of water injection system

・A water injection system is a system that injects a small amount of water droplets into an air-fuel mixture in the engine. It uses latent heat (evaporation heat) when the water evaporates to lower the temperature of the air-fuel mixture, improving engine fuel efficiency and exhaust gas reduction.

– By lowering the temperature of the air-fuel mixture, knock resistance is enhanced, bringing about various effects such as a higher compression ratio.

– The method of lowering the temperature of the air-fuel mixture during high-load operation generally requires fuel-rich mixture (increase in gasoline injection amount). Water injection replaces this principle with water. The latent heat of vaporized water (evaporation enthalpy) is 2257 kJ/L, which is about 5 to 6 times that of gasoline, having a high temperature reduction effect.

・Several systems have been developed such as direct water injection (DWI) and port water injection (PWI), or a combination of both.

Mass production of water injection systems

・Water injection has been used in mass-produced vehicles in the past. A recent example is the BMW M4 GTS released in fall 2015.

– Bosch has supplied the water injection system to the M4 GTS.

– The 3.0L inline 6-cylinder twin turbocharged gasoline engine is equipped with three port water injectors (PWI). Each injector injects water into two cylinders.

Issues with water injection systems

・The biggest challenge for water injection systems is securing water sources.

・The BMW M4 GTS has a 5.0L water tank. According to BMW’s announcement, the water tank must be refilled once after every five fuel refills under normal driving conditions. Water must be refilled more often under frequent high-load operation.

・Onboard water tanks add weight to the car. In order to reduce the amount of water used, the size, pressure, temperature, spray position, spray control and other factors of the water droplets need to be continuously improved.

・In order to reduce the size of the onboard water tank, a system for procuring necessary water from the air conditioner and circulating it in the car is also being studied.

Water Injection System:

Renewed Interest Driven by Meeting Euro 7 Emission Standards in the Early 2020s

Renewed interest in water injection systems

・Bosch has offered the water injection system of the BMW M4 GTS to other automakers as well, but mass production has yet to be launched since.

・However, recent reports on technical studies of water injection systems, such as those of European technology associations, have been on the rise again.

・These new studies are driven by introduction Euro 7 emission standards in the early 2020s.

– RDE (real driving emissions) tests will continue even after the implementation of Euro 7. In addition to nitrogen oxides (NOx), particulate matter (PM), particle number (PN), carbon monoxide (CO) is expected to be newly regulated.

– Automakers will be required to meet Euro 7 emission standards and improved fuel economy (reduce CO2).

RDE and full-load operation

・The technology for improving fuel efficiency through throttle control, which has been used as a natural solution for downsized gasoline engines, showed limited effect in RDE tests.

– In bench tests, it is enough to improve the efficiency at partial load, but in RDE tests one must consider operation at full load.

・In RDE tests, the engine operating range shifts toward higher brake mean effective pressure (BMEP). Although measures are taken to retard the ignition timing in consideration of knock limit, fuel economy worsens.

・In order to avoid the problem of lower knock limit (= worse fuel economy), water injection is considered as one solution.

Euro 7 is expected to regulate CO

・Exhaust gas from gasoline engines is usually removed by a three-way catalyst.

・The three-way catalyst works effectively only when the engine is running at stoichiometric (stoichiometric air-fuel ratio, λ = 1). NOx increases when the fuel is lean (λ > 1), and CO increases when the fuel is rich (λ < 1).

・To control NOx and CO in Euro 7 with RDE, stoichiometry (entire range λ = 1) is required throughout the engine operating range.

・Water injection is being considered as a measure to lower the exhaust temperature without using fuel rich mixture and to increase the specific output of the stoichiometric engine over the entire range.

(Created based on various media reports)

Please

register or subscribe to view this report for free.

If you’re already a subscriber, sign in.

Credit card information is not needed for free trial registration.

You are eligible to view one report for free.

Additional reports require subscription.